Ideal Practices for Preventing Weld Undercut: Understanding the Essentials

Ideal Practices for Preventing Weld Undercut: Understanding the Essentials

Blog Article

Comprehending the Causes and Solutions for Undercut Welding in Steel Manufacture Processes

In the realm of metal manufacture procedures, the occurrence of undercut welding positions a considerable obstacle that requires an extensive understanding of its causes and feasible remedies. The intricate interplay of various aspects throughout welding procedures can bring about this unwanted sensation, impacting the structural integrity and overall quality of the welded joints - Preventing weld undercut. By dissecting the source of undercut welding and checking out efficient restorative procedures, producers can raise the requirement of their craftsmanship and make sure the production of perfect metal components

Common Sources Of Undercut Welding

Often ignored in steel fabrication, undercut welding occurs due to various aspects that require meticulous attention and know-how to be properly mitigated. Furthermore, incorrect welding methods, such as making use of the incorrect welding angle or take a trip rate, can additionally add to damage development. The choice of welding parameters, such as voltage, current, and wire feed speed, plays a significant role in the occurrence of undercut welding.

Impact of Incorrect Welding Parameters

Incorrect welding specifications can substantially jeopardize the stability and high quality of welded joints in metal fabrication procedures. The influence of wrong welding criteria materializes in different methods, resulting in structural weak points and issues in the bonded elements. One vital aspect affected by inappropriate welding criteria is the infiltration depth of the weld. Insufficient heat input as a result of reduced welding currents or excessively high traveling rates can lead to inadequate blend in between the base metals, bring about insufficient joint penetration and weakened bonds. Alternatively, extreme heat input brought on by high welding currents or sluggish travel rates can result in too much and burn-through reinforcement, creating a breakable and unstable weld framework. Furthermore, wrong specifications such as improper voltage setups or incorrect electrode angles can add to erratic weld grain profiles, absence of fusion, and boosted chances of issues like undercutting. Consequently, careful attention to welding specifications is paramount to make sure the manufacturing of premium welds with the desired mechanical homes and architectural integrity.

Effect of Improper Torch Angle

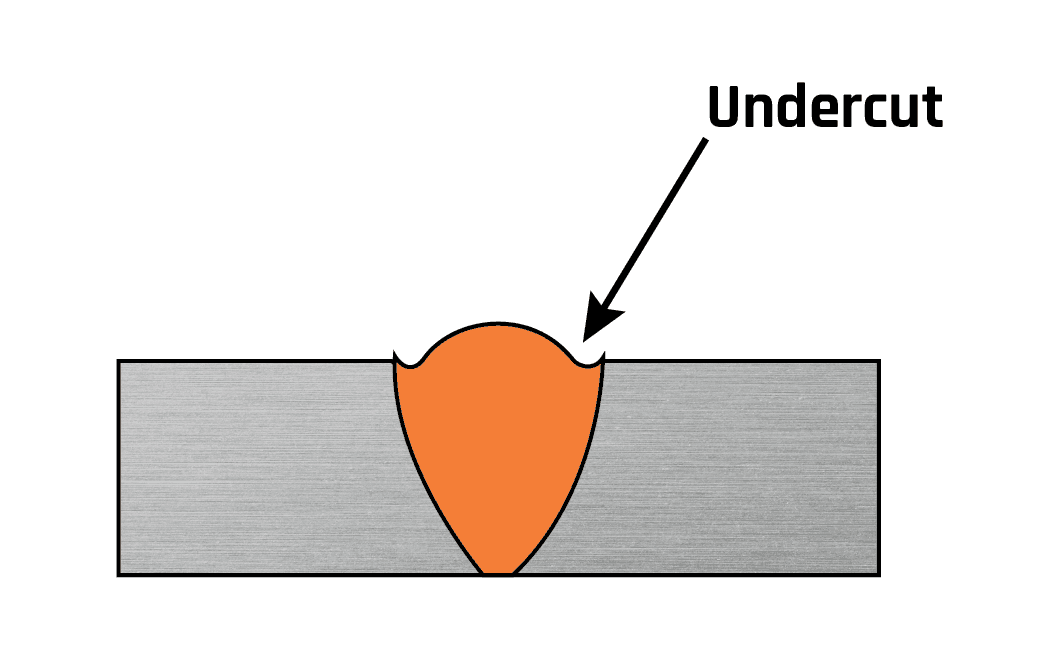

Incorrect torch angle in welding procedures can substantially affect the quality and honesty of the final weld joints in metal manufacture processes. Damaging is a typical welding defect where a groove creates along the weld toe, deteriorating the joint and jeopardizing its architectural stability.

A torch angle that is as well steep can cause insufficient infiltration, incomplete combination, and increased spatter. On the other hand, a lantern angle that is too superficial can result in extreme infiltration, burn-through, and distortion of the base material. Preventing weld undercut. Correct torch angle is necessary for ensuring constant weld top quality, strength, and look

To prevent undercutting and various other defects brought on by improper torch angles, welders need to be educated to maintain the right lantern angle throughout the welding procedure. Regular tracking and change of lantern angles throughout welding can help accomplish audio welds with marginal defects.

Function of Inadequate Welding Methods

One more facet of inadequate welding techniques is improper weld preparation. Insufficient cleansing of the base steels, wrong joint design, or insufficient edge preparation can all contribute to undercut welding. Additionally, poor securing gas protection or utilizing the incorrect kind of gas can cause insufficient blend and the development of undercut flaws.

To deal with the role of poor welding strategies in metal construction procedures, it is necessary to provide detailed training for welders. Proper education imp source on welding specifications, joint preparation, and protecting gas option can aid prevent undercut welding and ensure top notch welds in steel manufacture jobs.

Reliable Solutions for Undercut Welding

Addressing undercut welding in metal construction requires applying efficient options to improve weld high quality and architectural integrity. One of the main solutions to fight undercut is to change welding specifications such as voltage, current, and travel rate to guarantee appropriate heat input and fusion. By fine-tuning these setups, welders can avoid excessive melting of the base steel and filler product, reducing the chance of undercut formation.

In addition, proper joint prep work is vital in preventing undercut. Making sure tidy base steel surfaces complimentary of impurities and making use of the ideal bevel angle can help advertise far better weld infiltration and reduce the danger of undercut - Preventing weld undercut. Utilizing ideal welding techniques, such as oscillating the torch or weaving, can also help in dispersing warmth equally and filling the weld joint adequately, minimizing the possibility of undercut problems

Furthermore, picking the appropriate welding consumables, consisting of electrodes and filler metals, is crucial in mitigating undercut. Making use of products with appropriate important site chemical make-ups and mechanical residential properties can add to attaining sound welds with minimal undercut. Routine inspection and top quality control measures should additionally be carried out to identify and deal with undercut issues immediately, guaranteeing the general integrity of produced metal components.

Verdict

Finally, recognizing the reasons and services for undercut welding in steel manufacture processes is crucial for achieving premium welds. By attending to common reasons such as wrong welding parameters, incorrect torch angle, and insufficient welding techniques, welders can prevent damaging and make sure strong, long lasting welds. It is vital to take note of these variables and implement efficient options to improve the overall welding procedure and end product top quality.

Report this page